Assistant Clinical Professor Brittany Williams Brings Relief by Producing Ear-saving Gadgets

In the age of COVID-19, wearing a mask for the occasional trip to Safeway is a fleeting inconvenience. But for the doctors, nurses, grocery workers and other individuals on the front lines of the pandemic, faces masks are a fulltime requirement: and literally irritating.

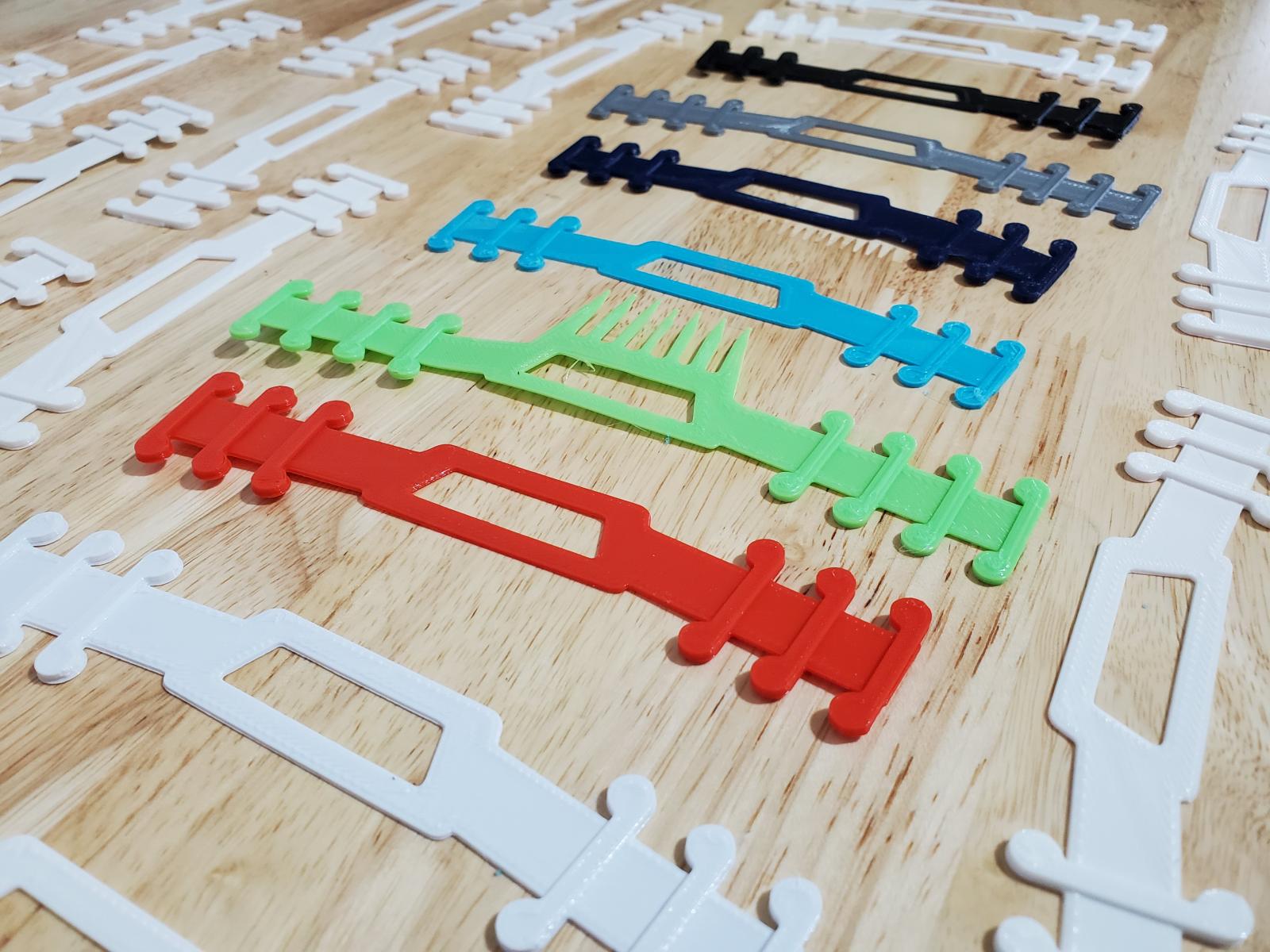

Rashes, breakouts—even skin lesions—are unfortunate side effects of prolonged mask use and are plaguing essential workers everywhere. It’s not something the average person thinks about, and didn’t cross Assistant Clinical Professor Brittany Williams’ mind—until her friend, who is a nurse, asked Williams if she could make her an “ear saver” with her 3D printer. Thin, flexible and roughly the size of a barbershop comb, earsavers bear the brunt of elastic earloops, protecting the ears from chaffing and delivering a more secure fit.

“In a situation like this when we all feel a bit helpless, I was looking for something to do,” says Williams (B.S. Architecture ’05, M.ARCH ’07). She had a 3D printer, but not the sterile environment, so face shields were out of the question. Earsavers, however, didn’t require a controlled environment for production. “When my friend asked if I could print one, I responded, ‘Print one? I can print you 100!’”

For the past month, Williams and her cousin, Matt Abel—a civil engineer who also has a 3D printer—have printed earsavers round-the-clock, producing over 1,000 for front line workers up and down the East Coast. With the help of friends, word-of-mouth and social media platforms like LinkedIn and Facebook, they’ve connected with hospitals, nursing homes and other essential businesses in need of relief: a medical professional at Johns Hopkins; the daughter of a former colleague; a friend from elementary school who works for a nursing home in Pennsylvania.

“It’s totally six degrees of separation,” said Williams. “Everyone knows someone who is in one of these essential industries.”

Each earsaver costs around nine cents to make, but Williams and Abel are absorbing the costs, delivering them free of charge. They plan to continue their efforts until they can no longer source filament, which is getting harder to find. According to Williams, it’s a small gesture that she hopes makes a difference in the comfort of those out in the field every day.

“These folks are putting themselves at risk every day. We just want to make that job a little easier.”